How Venturi Scrubbers Operate:

A venturi scrubber is designed to effectively use the energy from the inlet gas stream to atomizeVenturi Scrubber the liquid being used to scrub the gas stream. This scrubber is part of the group of air pollution control systems known as wet scrubbers. Apollo series air scrubbers effectively use the venturi configuration to remove particles from gas streams.

A venturi scrubber is designed to effectively use the energy from the inlet gas stream to atomizeVenturi Scrubber the liquid being used to scrub the gas stream. This scrubber is part of the group of air pollution control systems known as wet scrubbers. Apollo series air scrubbers effectively use the venturi configuration to remove particles from gas streams.

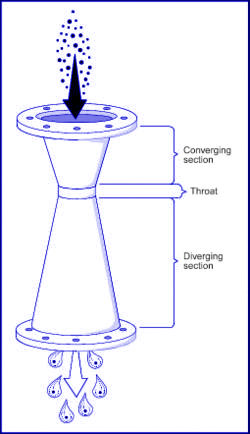

Venturi scrubbers consist of three sections: a converging section, a throat section, and a diverging section. The inlet gas stream enters the converging section and, as the area decreases, gas velocity increases. Liquid is introduced at the entrance to the converging section. The inlet gas, which is forced to move at extremely high velocities in the small throat section, shears the liquid from its walls, producing an tremendous number of very tiny droplets. In the throat section, particle and gas pollutant removal occurs as the inlet gas stream mixes with the fog of tiny liquid droplets. The inlet stream then exits through the diverging section, where it is forced to slow down. Venturi scrubbers can be used to collect both particulate and gas pollutants.

Venturi scrubbers can have the highest particle collection efficiencies of any wet scrubbing system, particularily for very small particles. They are used widely because their open construction helps to remove most particles without plugging or scaling. Venturi scrubbers have been designed to collect particles at very high collection efficiencies, sometimes exceeding 99%. The ability of venturis to handle large gas inlet volumes at high temperatures makes applicable to many industries.