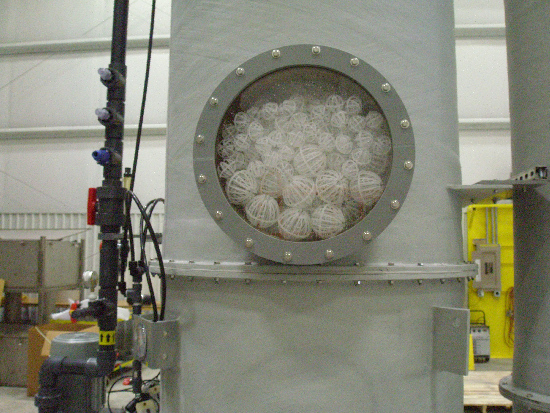

Packed tower air scrubber assemblies are used to remove vapor contaminants from an exhaust gas stream by way of absorption. Developed in the early 1900s, this continues to be the most efficient method of carrying out mass transfer between gas and liquid phases. Packed tower scrubbers incorporate packing media to facilitate intimate contact between a scrubbing liquid and gas to be scrubbed. Applications range from product recovery to air pollution and odor control. In countercurrent scrubber operation, the gas flows upward through the bed, while the liquid irrigates downward by gravity through the bed. The liquid wets the myriad surfaces of the packing material, providing a large amount of surface area for diffusion of one or more components of the gas stream into the liquid stream, thereby purifying the gas. Advantages include: Packing media falls into one of two general categories, random dump or structured. Random dump packing consists of relatively small individual pieces of a given shape being literally dumped into the tower until the prescribed bed height is achieved. The individual pieces for random dump packing range in size from 5/8 inch to 3.5 inches. Structured packing consists of large pieces that are placed individually in the tower in a specific orientation. Structured packing is more expensive than random dump packing, and is harder to install. However, it can accomplish the same scrubbing efficiency as random dump packing but at a much lower pressure drop, i.e., using less energy.