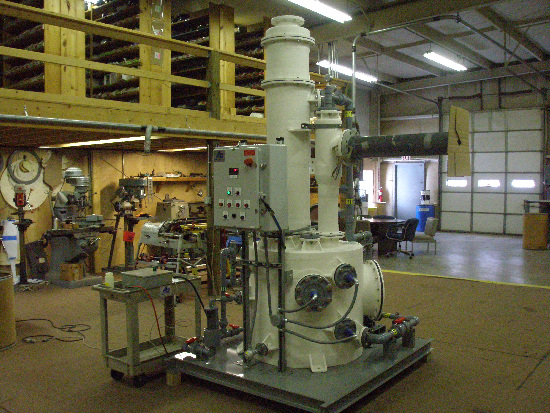

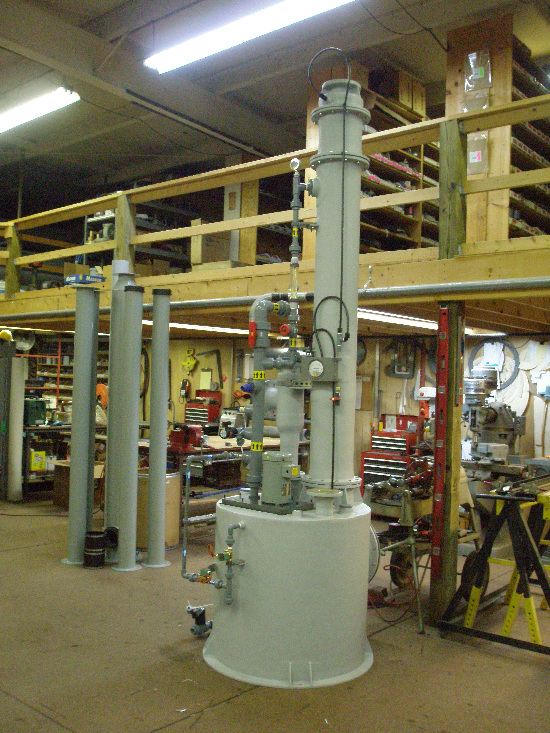

The Apollo Series™ represents an efficient and compact packed tower Venturi Air Scrubber system for the capture and destruction of acid gases or other compounds. The ejector/venturi design creates suction at the inlet, eliminating the need for a blower. The unit’s small footprint makes it ideal for point of source applications, or where space is limited. The Apollo Series™ venturi scrubbers can be operated in a batch process or completely automated with a full array of control options to meet your specific needs. Applications include chemical storage tanks, refilling operations, reactor vents, chemical vapor deposition systems, cylinder gas vents and industrial processing, to name just a few. CLICK HERE for Venturi Scrubber CAD Drawings CLICK HERE to see how Venturi Scrubbers Operate Gas & Particle Removal Efficiency in Action

Features and benefits:

The Apollo Series Venturi Air Scrubbers can be custom configured as:

Standard specifications:

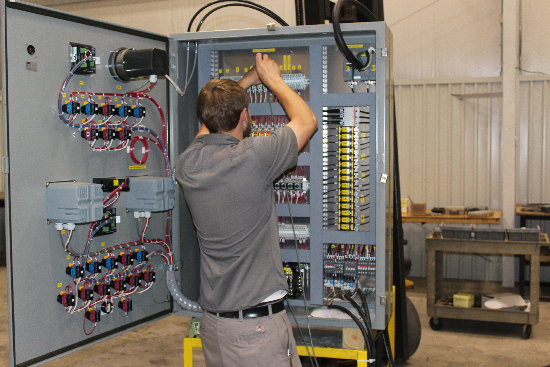

Options: