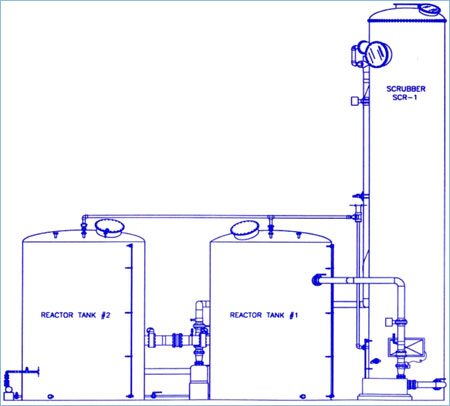

Advanced Air Technologies offers a combination of scrubbing equipment to accomplish ethylene oxide (EtO, EO) and propylene oxide (PO) abatement regulation for industrial and commercial applications. Combining the Orion Series™ Epoxide Scrubber and the Safe-Cell II DR490 series Gas/Solid Reactor Dry Bed proprietary process tackles all your abatement requirements. Many of our installed systems operate at over 10,000 cubic feet of airflow per minute on a continuous basis. The Safe-Cell DR490 series Gas/Solid Reactor Dry Bed offers more than 99% efficiency with a safety record that is unparalleled compared to thermal oxidation.

No other air scrubber supplier can match the experience of AAT in the design and operation of epoxide scrubber systems. AAT has been building ethylene oxide (EO or EtO) and propylene oxide (PO) abatement systems since 1987 and we understand the intricate design considerations that are unique to this application. Our Orion Series™ EO / PO wet chemical scrubber systems are tailored to your detailed specifications and plant characteristics. Our design flexibility allows the use of preferred components and materials, ensuring that our system can be fully and safely integrated into your existing plant environment and methodologies. The technology used in our epoxide scrubber systems is the safest of all technologies available. We guarantee compliance to all federal, state and local emissions requirements. Entrust the safety of your plant and your personnel to a manufacturer with extensive epoxide scrubbing experience. Typical Industry Applications Gas/Solid Reactor Dry Bed Ethylene Oxide Air Scrubbers The Safe Cell II is a proprietary high-volume dry bed filter used to safely destroy EtO. The key to the process is our proprietary chemical reactant material that destroys the EtO. The spent reactant may be easily disposed in non-hazardous landfills. Check with your local waste management company Purchase a Safe-Cell II Model DR-490 Series Gas/Solid Reactor Dry Bed System and eliminate Ethylene Oxide (EtO) emissions from your facility. Applications include backvents, aeration room exhausts, door hoods, and other fugitive emissions. Another common use for the DR-490 Solid Gas/Solid Reactor Dry Bed is a polisher following our Orion Series™ EO/PO scrubber systems. We guarantee compliance with state and federal NESHAP regulations. Epoxide Scrubbers, EtO, EO, PO Scrubbers

Safe Cell II #DR-490 Gas/Solid Reactor Dry Bed

Features & Benefits of # DR-490 Series Gas/Solid Reactor Dry Bed

Safe Cell II #DR-490 Gas/Solid Reactor Dry Bed

Specifications *

#DR-490 Gas/Solid Reactor Dry Bed Standard Equipment Package

Options

Features